Beaumont, Texas 77705 | Directions

(409) 722-9625 fax

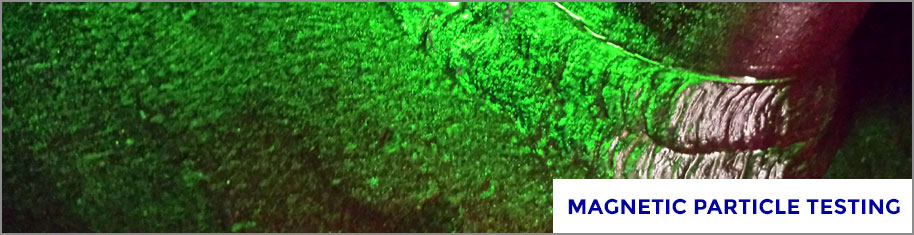

Magnetic Particle Testing

Magnetic particle testing, sometimes called mag particle, MPI, or MT, is ideal for identifying surface or near-surface discontinuities in parts and assemblies whose materials have a certain degree of magnetism, such as billets, bars, castings, forgings, fasteners, weldments, brazes, and extrusions.

How does magnetic particle examination work?

Magnetic particle inspection is a nondestructive testing (NDT) process for detecting surface and subsurface discontinuities in ferrous materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part and the piece is magnetized by direct or indirect magnetization.

Wet MT and dry MT methods

The presence of a surface or subsurface defect or discontinuity in the material allows the magnetic flux to leak. Ferrous iron particles are applied to the part in a dry or in a wet suspension, these variations can be referred to as dry magnetic particle inspection or wet magnetic particle inspection. If an area of flux leakage is present, the particles will be attracted to the defect. The particles will build up around the leakage and form an "indication." The indication is evaluated to determine its characteristics, its cause, and how to proceed.

Magnetic Particle Gallery

APPLIED STANDARDS INSPECTION

4781 Hwy 69 S

Beaumont, Texas 77705

Phone: 409-721-5800

Fax: 409-722-9625

Inspection Services